Expert support for custom inductors and other challenging magnetics.

When you have a difficult inductance target or are scrambling to meet a deadline, Spang Engineered Solutions can take the problem of inductor design off of your hands and help you complete your project successfully.

Custom Parts

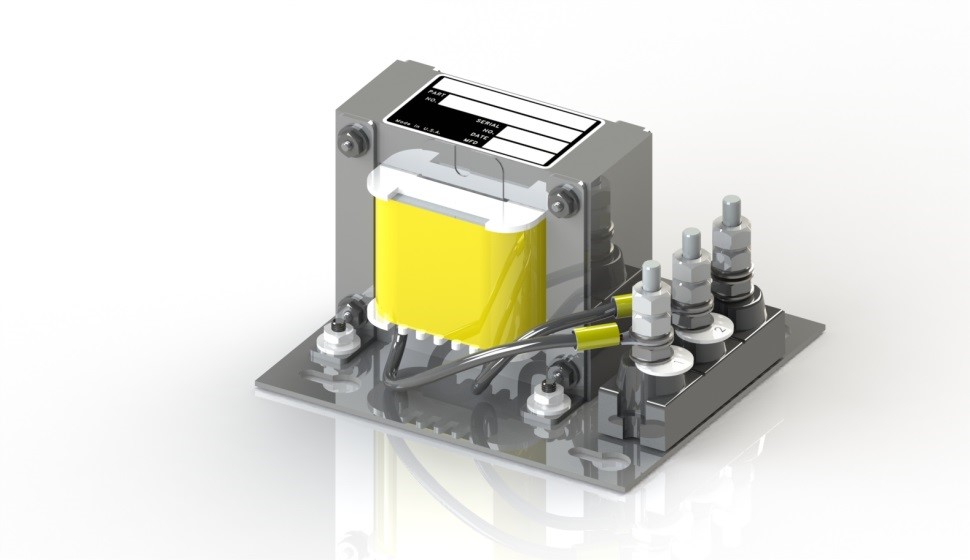

Our specialty is high power inductors. Using advanced design tools, our electrical design engineers typically prepare multiple alternatives for initial review. By presenting options side-by-side, our design team can help you to see clearly the tradeoffs that are available. This helps to find the best-optimized solution. It also helps to show quickly whether Spang Engineered Solutions may be a good fit for your business.

Sizes

Experience with large chokes makes us unique, but our engineers can design for any power level. Whether you need 5 ?H at 2 A, or 50 ?h at 700 A, we can offer you options, and help you get to a solution fast.

|

Other Components And we do more than design and build inductors. We meet tough challenges with all types of magnetics and magnetic assemblies. |

|

Versatility

Spang Engineered Solutions can review an existing magnetic design to help find improvements or make necessary changes. Or we can help lay out the initial requirements for a brand new magnetic. Our scope includes a wide range of core materials and custom bobbin types, plus the potting materials and mounting fixtures best suited for each application. Each project is unique, and we adapt our approach each time to give our customer just the support desired, and arrive at just the solution needed.

|

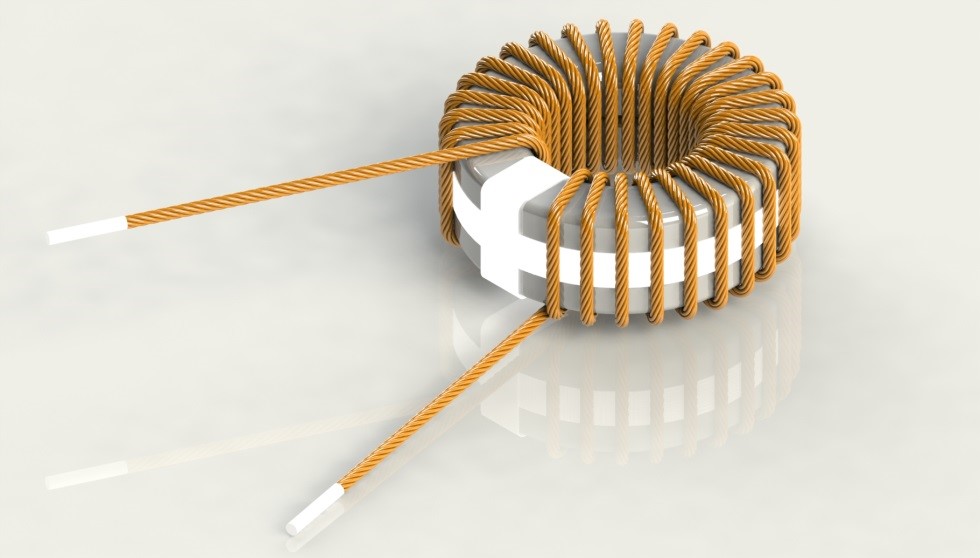

Toroid Winding

All core materials, including Kool M?, XFlux, MPP, Ferrite, Silicon Steel, Iron Powder, Amorphous/Nanocrystalline, and High Flux |

|

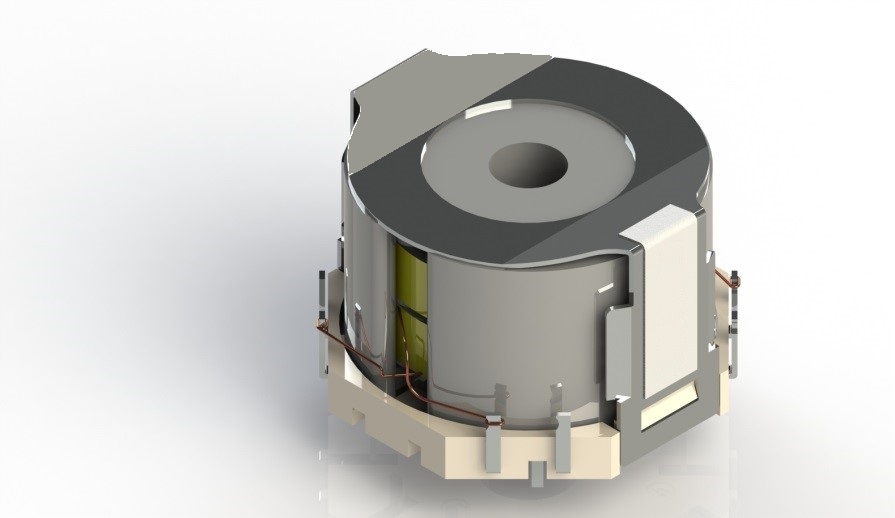

Customized Fixturing

|

|

|

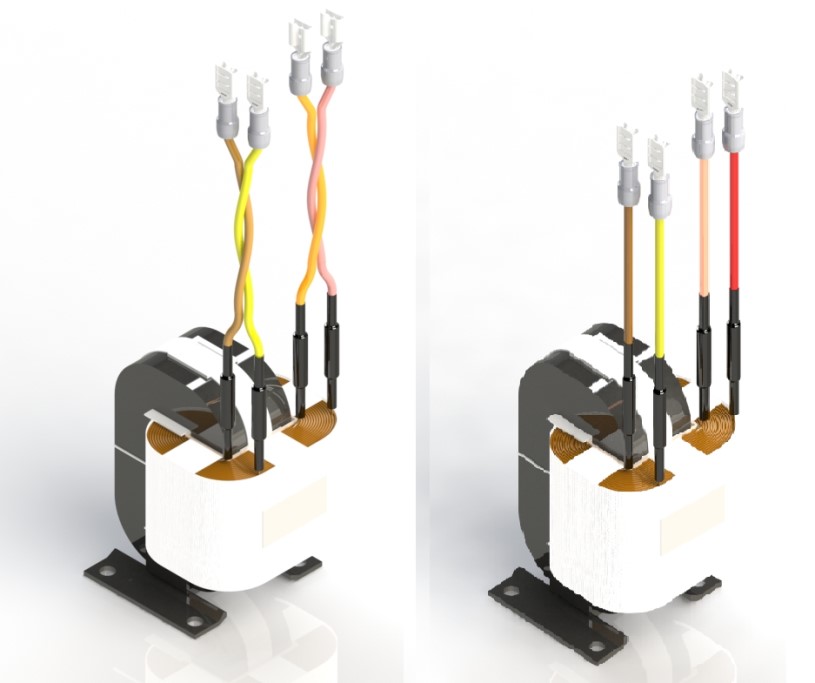

Non-Toroidal Magnetics

|

|

Optimization and Options Try it more than one way? ??in design Faster turnaround for more iterations Better results, sooner |

|

|

Integrated Design and Assembly Just the magnetic? ?or the higher level component Whichever best suits your need Whichever simplifies your project |

|

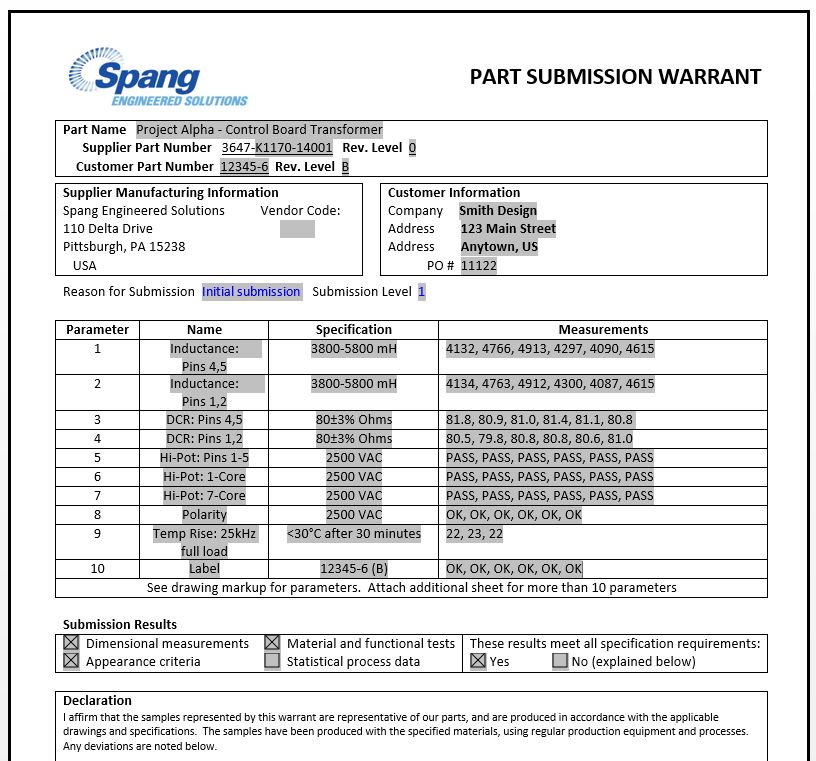

Qualification Systems

|

|

With comprehensive design capabilities as well as the ability to manufacture your inductors quickly, we can make the completion of your project simpler. If you have a difficult target or are looking for design and manufacturing help, allow Spang Engineered Solutions to meet your needs.