Inductor simulation for high power inductor design

Simulation during inductor design is important for discovering potential benefits and exploring tradeoffs, before any manufacturing begins. Spang Engineered Solutions has drawn on decades of experience of our sister companies, Magnetics and Spang Power Electronics, to develop proprietary inductor simulation algorithms. We can evaluate multiple approaches, all before any prototyping is started.

Our modeling tools allow us to simulate inductor operation across a wide range of frequencies, power levels, and wave shapes. Virtually any user-defined combination of ripple waveform and fundamental waveform can be evaluated.

SES modeling is empirical, meaning it is based on the real-world performance of magnetic cores and windings. Inductance, current and voltage responses in the simulations are accurate representations of what will happen in actual components, because the components are modeled for their real behavior. From those practical results, loss estimates are calculated and expressed in the form of core loss, copper loss, temperature rise, and/or efficiency. It is a more realisitic approach to simulation than trying to predict the actual performance of magnetic components using FEA models and field calculations.

The SES magnetic simulation tools allow us to better meet your company?s needs, and to design the best custom inductor to fit your purpose. You can see waveforms of voltage, current and inductance, plus calculated inductance and power loss, all before proceeding to the prototype build.

|

|

Inductor Model Simulated and Tested

|

|

|

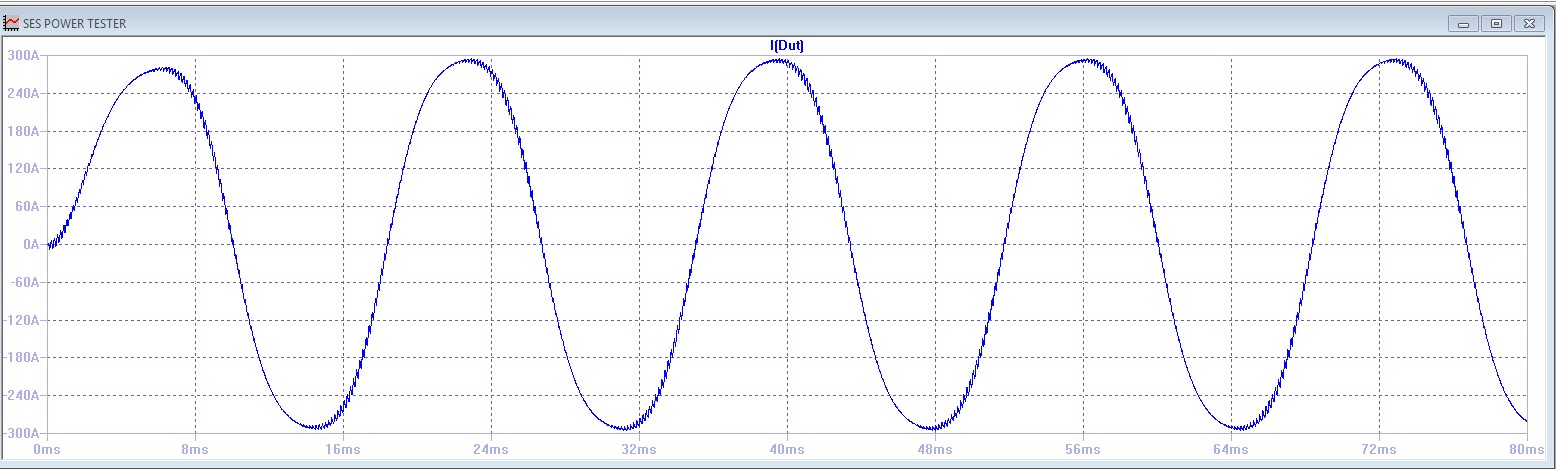

Simulation Result ? Current Waveform

|

|

|

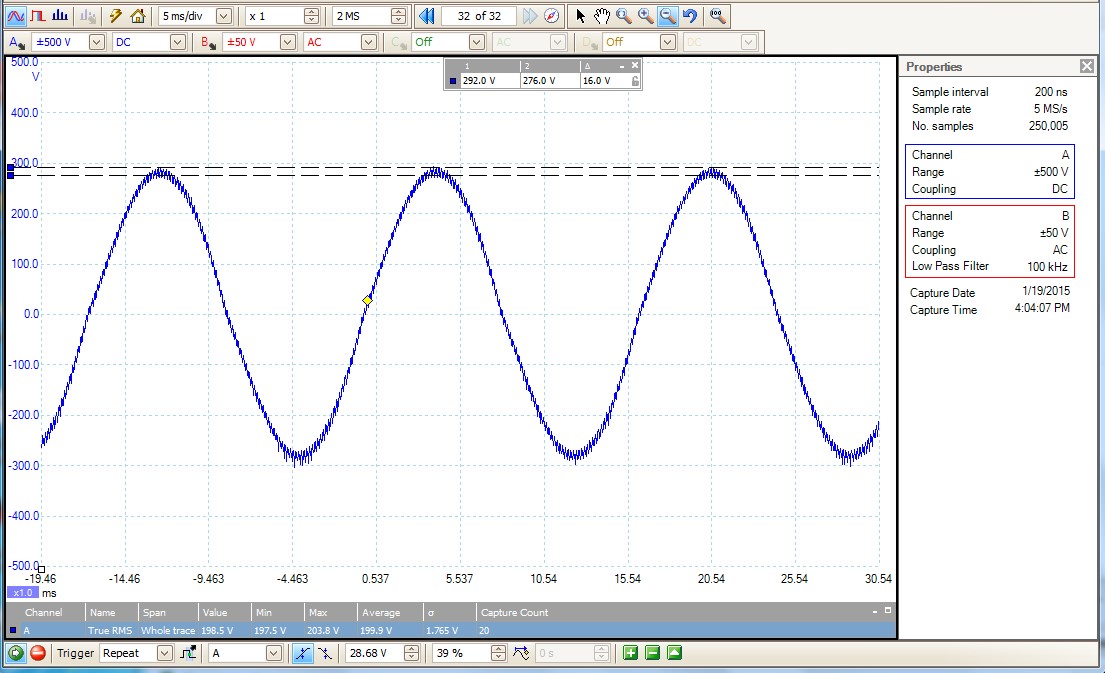

Test Result ? Current Waveform

|